Could Remote Monitoring be the Answer to Legionella Prevention?

By Uwe Klatt, Vice President of Sales at Disruptive Technologies.

By Uwe Klatt, Vice President of Sales at Disruptive Technologies.

Legionella prevention is one of the many ongoing concerns that facilities managers have to deal with. In normal circumstances, when offices, schools, hotels and shops are occupied and busy, it’s something that needs to be monitored but that will largely take care of itself. Regular pipework flushing to prevent the pathogen forming in under utilised taps and outlets may still be required. The problem is that the last twelve months have been far from ‘normal’. With the various periods of lockdown seeing public spaces abandoned for prolonged intervals, disused pipework could easily become home to the bacteria. Indeed, data from The Lancet 1 suggests that the potential for a legionnaire’s disease outbreak this spring is very real.

So, what can facilities managers do to minimise the risk? Is there an easier way to manage legionella prevention?

The application of smart tech for legionella management

Smart technology, powered by the Internet of Things (IoT), has become an increasingly valuable resource in facilities management. With the power to monitor and control energy use, building health, and a range of cost-saving and sustainability features, from any location, smart tech streamlines and simplifies previously time-hungry activities. With remote monitoring, legionella control instantly becomes simpler, more effective and less wasteful.

The key advantages of smart monitoring in legionella control

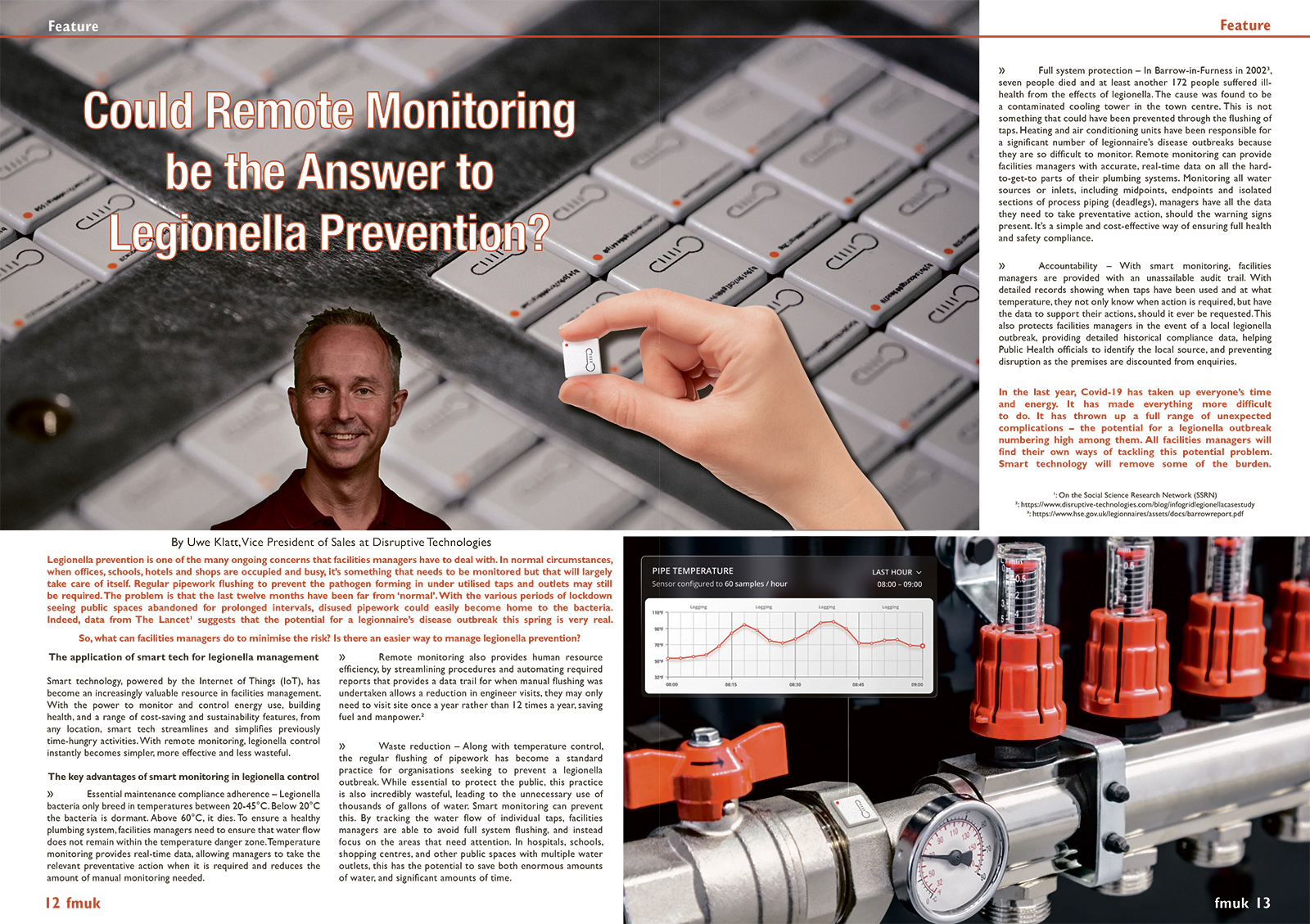

- Essential maintenance compliance adherence – Legionella bacteria only breed in temperatures between 20-45°C. Below 20°C the bacteria is dormant. Above 60°C, it dies. To ensure a healthy plumbing system, facilities managers need to ensure that water flow does not remain within the temperature danger zone. Temperature monitoring provides real-time data, allowing managers to take the relevant preventative action when it is required and reduces the amount of manual monitoring needed.

- Remote monitoring also provides human resource efficiency, by streamlining procedures and automating required reports that provides a data trail for when manual flushing was undertaken allows a reduction in engineer visits, they may only need to visit site once a year rather than 12 times a year, saving fuel and manpower.

- Waste reduction – Along with temperature control, the regular flushing of pipework has become a standard practice for organisations seeking to prevent a legionella outbreak. While essential to protect the public, this practice is also incredibly wasteful, leading to the unnecessary use of thousands of gallons of water. Smart monitoring can prevent this. By tracking the water flow of individual taps, facilities managers are able to avoid full system flushing, and instead focus on the areas that need attention. In hospitals, schools, shopping centres, and other public spaces with multiple water outlets, this has the potential to save both enormous amounts of water, and significant amounts of time.

- Full system protection – In Barrow-in-Furnace in 2002, seven people died and at least another 172 people suffered ill-health from the effects of legionella. The cause was found to be a contaminated cooling tower in the town centre. This is not something that could have been prevented through the flushing of taps. Heating and air conditioning units have been responsible for a significant number of legionnaire’s disease outbreaks because they are so difficult to monitor. Remote monitoring can provide facilities managers with accurate, real-time data on all the hard-to-get-to parts of their plumbing systems. Monitoring all water sources or inlets, including midpoints, endpoints and isolated sections of process piping (deadlegs), managers have all the data they need to take preventative action, should the warning signs present. It’s a simple and cost-effective way of ensuring full health and safety compliance.

- Accountability – With smart monitoring, facilities managers are provided with an unassailable audit trail. With detailed records showing when taps have been used and at what temperature, they not only know when action is required, but have the data to support their actions, should it ever be requested. This also protects facilities managers in the event of a local legionella outbreak, providing detailed historical compliance data, helping Public Health officials to identify the local source, and preventing disruption as the premises are discounted from enquiries.

In the last year, Covid-19 has taken up everyone’s time and energy. It has made everything more difficult to do. It has thrown up a full range of unexpected complications – the potential for a legionella outbreak numbering high among them. All facilities managers will find their own ways of tackling this potential problem. Smart technology will remove some of the burden.

1: On the Social Science Research Network (SSRN)

Click the article to enlarge it.